Video

1 / 7

ABS Plastic Shell Injection Molded Parts

Options:

- ABS injection

| Model No. : | M790 |

|---|---|

| Brand Name : | One-Stop |

| Tolerance : | 0.003mm-0.01mm |

Guangzhou, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

Product description

ABS Plastic Shell Injection Molded Parts

Plastics for injection molding are generally divided into ordinary grades,

high flow grades and ultra-high flow grades. Due to its good fluidity,

it is suitable for large products and small precision products; although

fluidity is good for large objects, small objects with high degrees also

have their own advantages. The above is a simple analysis of ABS.

CUSTOMIZED SERVICE

●We can provide customization in different structure, size,logo and package so long as you provide design.

We also can provide ODM service

●We can customize all kinds of Engineering plastics products according to customers’drawings or samples.

name

Professional high-precision molds and Injection Molding Parts

color

white,black,green,nature,blue,yellow,etc

material

ABS,PMMA,PC,PP,PEEK,PU,PA,PA+GF,POM,PE,UPE,PTFE,etc

mould cavity

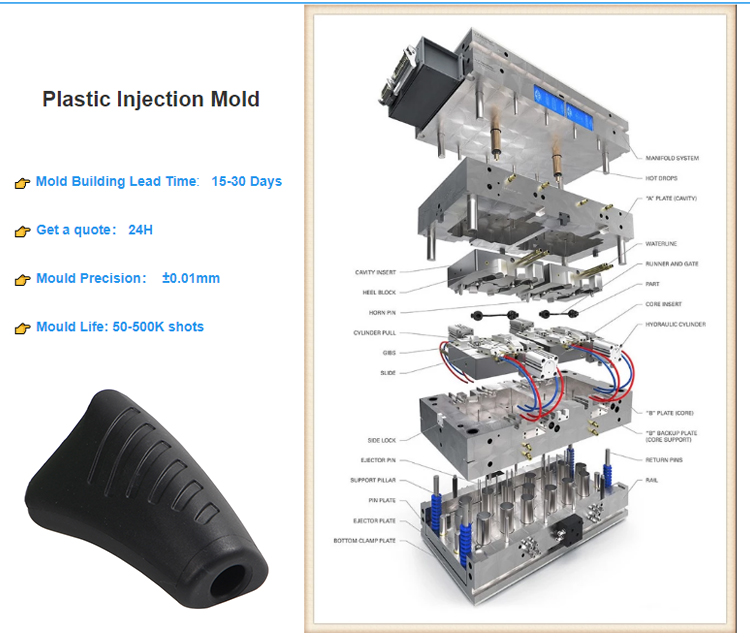

single cavity & multi cavity

runner system

hot runner and cold runner

equipment

CNC, EDM, cutting off machine,plastic machinery etc

certification

ISO9001 and relate whole set professional test report

Application field

Various plastic injection molded parts for various industrial and automotive applications

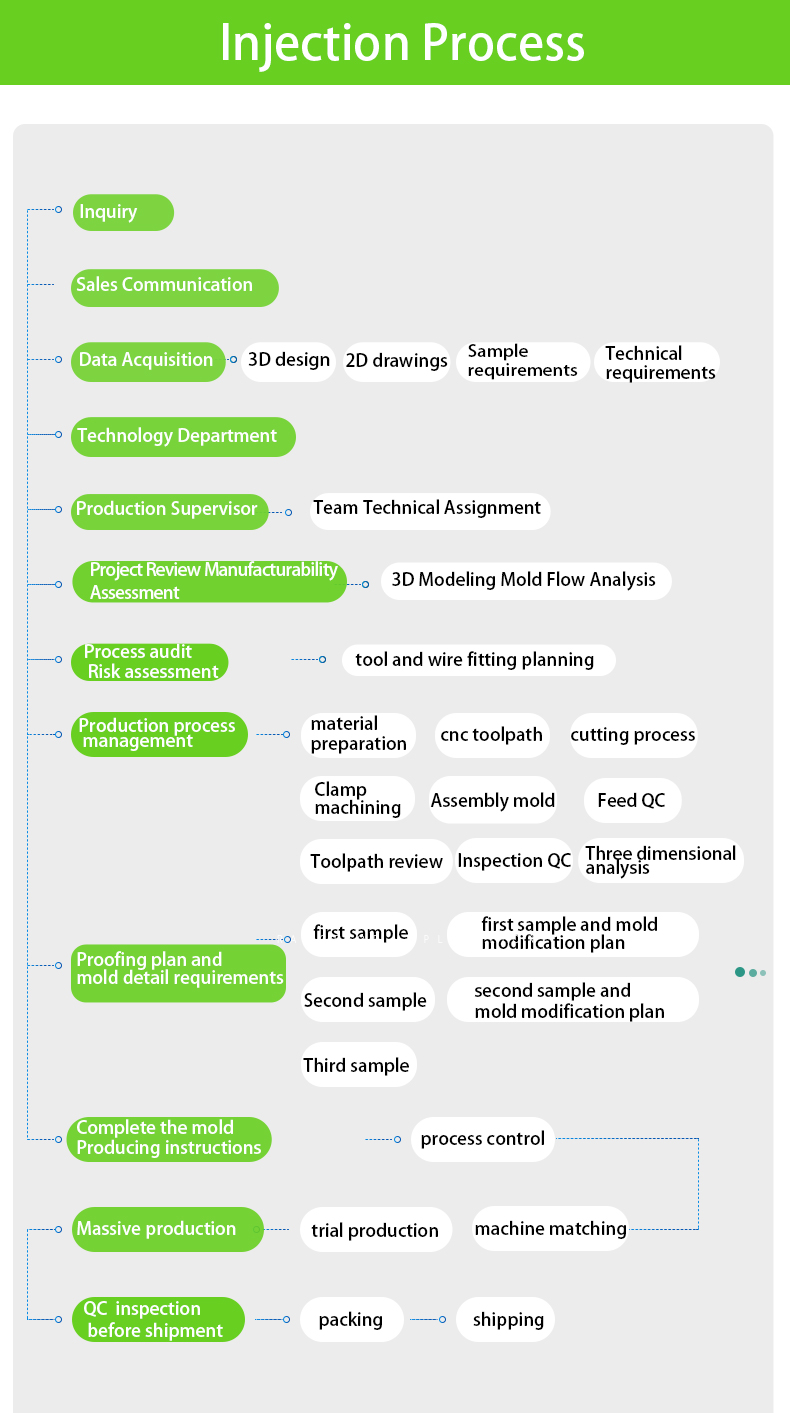

lead time

25-35 days for mould,plastic products according to quantity

other

24 hours instant and comfortable customer service

shipping status notification during delivery

regular notification of new styles & hot selling styles

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for

producing parts by injecting molten material into a mould, or mold. Injection moulding

can be performed with a host of materials mainly including metals (for which the

process is called die-casting), glasses, elastomers, confections, and most commonly

thermoplastic and thermosetting polymers. Material for the part is fed into a heated

barrel, mixed (using a helical screw), and injected into a mould cavity, where it cools

and hardens to the configuration of the cavity.After a product is designed, usually by

an industrial designer or an engineer, moulds are made by a mould-maker (or toolmaker)

from metal, usually either steel or aluminium, and precision-machined to form the

features of the desired part. Injection moulding is widely used for manufacturing a

variety of parts, from the smallest components to entire body panels of cars.

Advances in 3D printing technology, using photopolymers that do not melt during

the injection moulding of some lower-temperature thermoplastics, can be used for

some simple injection moulds.

Moulding Injection Products Description

For injection molding, the products will be sent for 15 days. And we support OEM and ODM.

Video

Guangzhou, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

Send your inquiry to this supplier