1 / 9

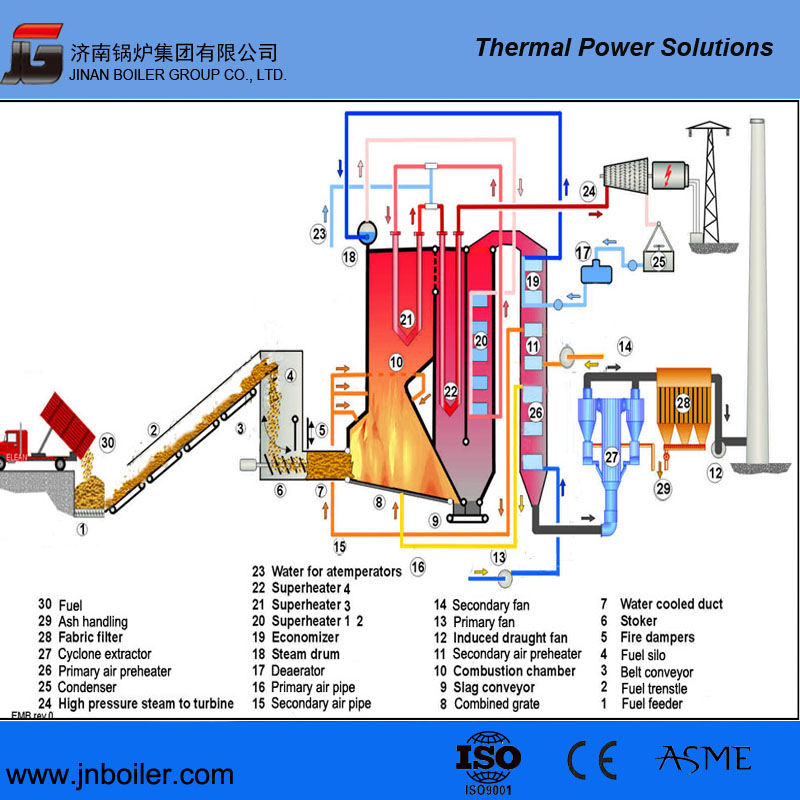

35 T/H Water-Cooling Vibrating Grate for Power Plant

| Model No. : | 35 T/H |

|---|---|

| Brand Name : | JIGUO |

| Function : | Steam Boilers |

Product description

1. Dominant product-biomass boiler:

Jinan Boiler Group Co., Lt.d is the largest biomass boiler research and development base and develops various types and series of biomass boilers. This series of product has the advantages of energy saving and environmental protection. JBG has three kinds of biomass boiler technology, combined grate, water-cooling vibrating grate and Circulating Fluidized Bed. Since the operation of the first 130t/h biomass boiler in China in 2006, JBG has supplied more than 200 sets of biomass boilers.

2. Biomass boiler parameter:

|

Description |

PARAMETER |

|

rated capacity |

35 t/h |

|

rated steam pressure |

9.8 MPa |

|

rated steam temperature |

540ºC |

|

rated water feeding temperature |

215ºC |

|

applicable fuel |

Palm Fiber etc. |

|

guarantee heat efficiency |

90% |

Other Product series

|

No. |

Boiler Model |

Capacity, t/h |

Steam pressure,Mpa |

Steam Temperature,ºC |

No. |

Boiler Model |

Capacity, t/h |

Steam pressure,Mpa |

Steam Temperature,ºC |

|

1 |

YG-240/9.8-T |

240 |

9.8 |

540 |

21 |

YG-95/5.29-T |

95 |

5.29 |

485 |

|

2 |

YG-240/5.29-T |

240 |

5.29 |

485 |

22 |

YG-95/3.82-T |

95 |

3.82 |

450 |

|

3 |

YG-240/3.82-T |

240 |

3.82 |

450 |

23 |

YG-85/9.8-T |

85 |

9.8 |

540 |

|

4 |

YG-220/9.8-T |

220 |

9.8 |

540 |

24 |

YG-85/5.29-T |

85 |

5.29 |

485 |

|

5 |

YG-220/5.29-T |

220 |

5.29 |

485 |

25 |

YG-85/3.82-T |

85 |

3.82 |

450 |

|

6 |

YG-220/6.4-T |

220 |

6.4 |

455 |

26 |

YG-75/9.8-T2 |

75 |

9.8 |

450 |

|

7 |

YG-220/3.82-T |

220 |

3.82 |

450 |

27 |

YG-75/9.2-T |

48 |

9.2 |

540 |

|

8 |

YG-170/9.8-T |

170 |

9.8 |

540 |

28 |

YG-75/5.29-T |

75 |

5.29 |

485 |

|

9 |

YG-170/5.29-T |

170 |

5.29 |

450 |

29 |

YG-75/3.82-T |

75 |

3.82 |

450 |

|

10 |

YG-170/3.82-T |

170 |

3.82 |

450 |

30 |

YG-65/9.8-T |

65 |

9.8 |

540 |

|

11 |

YG-150/9.8-T |

150 |

9.8 |

540 |

31 |

YG-65/5.29-T |

65 |

5.29 |

485 |

|

12 |

YG-150/5.29-T |

150 |

5.29 |

540 |

32 |

YG-65/3.82-T |

65 |

3.82 |

450 |

|

13 |

YG-150/3.82-T |

150 |

3.82 |

450 |

33 |

YG-50/5.29-T |

50 |

5.29 |

485 |

|

14 |

YG-130/11.5-T |

130 |

11.5 |

535 |

34 |

YG-50/3.82-T |

50 |

3.82 |

450 |

|

15 |

YG-130/9.8-T |

130 |

9.8 |

540 |

35 |

YG-48/9.2-T |

48 |

9.2 |

540 |

|

16 |

YG-130/9.8-T1 |

130 |

9.8 |

540 |

36 |

YG-45/5.29-T |

45 |

5.29 |

485 |

|

17 |

YG-130/9.2-T |

130 |

9.8 |

540 |

37 |

YG-45/3.82-T |

45 |

3.82 |

450 |

|

18 |

YG-130/5.29-T |

130 |

5.29 |

485 |

38 |

YG-35/5.29-T |

35 |

5.29 |

450 |

|

19 |

YG-130/3.82-T |

130 |

3.82 |

450 |

39 |

YG-35/3.82-T |

35 |

3.82 |

450 |

|

20 |

YG-95/9.8-T |

95 |

9.8 |

540 |

|

|

|

|

|

3. Biomass boiler types and features:

Boiler Type Featurescombined grate 1. stepped and travelling grate

2. better adjustment performance

3. suitable for high moisture

4. suitable for a variety of fuels

circulating fluidized bed 1. suitable for hard fuel

2. high combustion efficiency

3. stable operation control

4. wide load control range

water cooling vibrating grate 1. techonology from Europe

2. directional combustion

3. suitable for single fuel

4. high combustion efficiency

4. Biomass boiler burning fuel:

*Agriculture waste: wheat straw, corn straw, cotton, peanut straw, rice straw, sugarcane leaves, rice husk, peanut shells, corn cob, bagasse, palm fiber, palm shell, empty fruit bunch(EFB)

*Forest waste: Wood piece, wood chip, sawdust, wood branch, bark, leaves, green mud etc.

*Industial waste: Cloth, paper, rubber, plastics, leather, sludge, medical waste etc.

5. Company introduction:

Established in 1954, Jinan Boiler Group Co., Ltd. ( Hereinafter called "JBG" ) is a large backbone company that manufactures Grade "A" power boilers and industrial boilers in China, and is also one of the leading companies for CFB boiler and biomass boilers. With the total asset value being over RMB 2 billion, JBG has 1300 employees, including 300 engineering technical staff. Located in the famous historical and cultural city -Jinan, the capital of Shandong Province, which is called "City of Springs".

Majoring in the manufacture of power boilers and industrial boilers, JBG integrates the research & design, manufacture, auxiliaries supply, installation, maintenance, alteration, power plant EPC, environmental project EPC and technology consultation, and tries to step over from a single boiler supplier to an EPC contractor.

Adhering to the business principle "dedicating clean energy, making green products, improving economic benefit and building harmonious enterprise", JBG develops the first circulating fluidized bed power boiler in China, introduces and digests the 100% biomass power boiler technology and manufactures the first 30MW biomass power boiler in China. Now, JBG has grown up to be a globally-known CFB (Circulating Fluidized Bed) boiler research base and the largest biomass fired boiler manufacture base, and JBG is one of high-tech enterprises in Shandong Provence and recognized as an experimental base by the Thermophysics Institute of China Academy of Science. JBG positively follows the low carbon economy trend and development of new energy industry and vigorously develops CFB boilers, biomass power boilers etc. for energy conservation and environmental protection. Now, JBG has developed more than 10 series and 100 types of products including CFB boilers, biomass boilers, pulverized-coal fired boilers, hot water boilers, waste heat recovery boilers, chemical recovery boilers, oil/gas fired boilers, waste incineration boilers, De-Sox & De-NOx products and pressure vessels etc.. The products are popular in China and exported to many countries, including Japan, Belgium, Singapore, Indonesia, Malaysia, Thailand, Pakistan, India, Viet Nam, Cambodia, Mongolia, Nigeria, Rwanda etc.

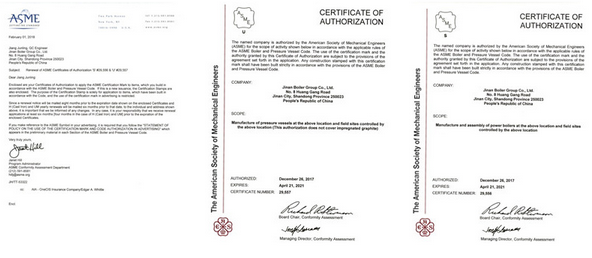

6.Company certificates:

Send your inquiry to this supplier