1 / 1

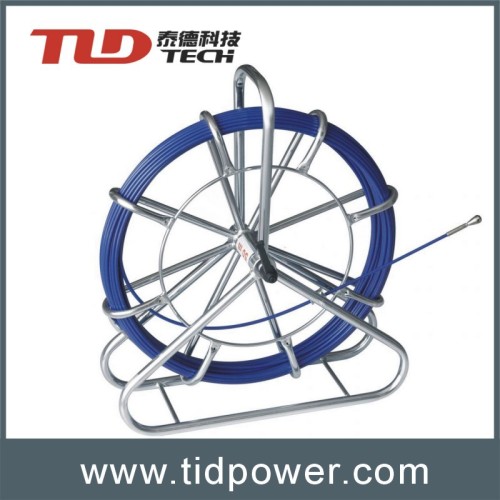

Duct rodders

| Model No. : | TID-03 |

|---|

Product description

Specifications

2.Excellent Flexibility Force

3.ISO9001, various sizes

4.Anti-corrossion

TID Tech offers one of the most comprehensive range of Duct Rodders available anywhere in the world - from the smallest Φmm 4.5 to Φ16mm Duct Rodders.

1.Material :

THE ROD

TID rods are manufactured from state-of-the-art materials formulated to offer the high performance & durability demanded by our customers.

The core of the rod is manufactured by the pultrusion process. This involves impregnating high strength continuous glass fiber filaments with a liquefied resin.

The fibers are drawn in to a heated die where the resin matrix is cured, bonding the fibers together and allowing mechanical loads to be transmitted through the matrix and distributed amongst the fibers.

THE FraMes

Frames are also a feature of the TID Tech systems. a larger footprint for stability; steel brake handles that will last forever; dual rod out-feeding positions and wheels inside the frame width.

2.Technical Specification

2.1.Glass reinforced Composite Core:general properties

|

Property |

Value |

|

Keinforcement |

E-glass fiber |

|

Glass content of inner part |

75-80% |

|

Material of pulling rod |

epoxy fiber glass(inner) high density polyethylene(outer) |

|

Density |

>1.9gr/cm3 |

|

Diameter tolerance |

+/-0.10mm |

|

Work situation temperature |

-40°C to +80°C |

2.2.Mechanical Prperties

|

Property |

Value |

|

|

Minimum pullling strength |

4000 N+/-5% |

|

|

Tensile modulus |

>30000Mpa |

|

|

Consistency of rod |

150gr/m +/-5% |

|

|

Flexural modulus |

>30000M pa |

|

|

Elongation at break |

2.5-3% |

2.3. Polyethylene Cover

|

Property |

Value |

|

Tensile strength |

>15N/mm2 |

|

Environmental stress & crack resistance |

>1000 hr. |

|

Heat stability |

OK. |

|

Carbon black |

OK. |

Fiberglass duct rodders are used for communication and Drain cleaner and electric power pull.

roD seleCtIon

roD seleCtIon

Which is the right rod diameter for any given application? The rod selection is usually governed by several factors including:

• The size of ducting it is to be pushed through

• The distance the rod is to be pushed

• The number and tightness of bends in the ducting

• If the ducting is already occupied by cable

When being pushed through the duct, any rod will tend to form [sine waves", hitting the wall of the duct at certain intervals. Each time the rod comes in contact with the wall of the duct, it causes friction. The friction will build and eventually prevent the rod from being pushed any further. Small rod in large duct will make more frequent contact with the ducting; the same rod in smaller duct will make less frequent contact and therefore less friction so it can be pushed further. Large rod in small ducting is a good situation, but reduced flexibility of the rod may cause increased friction in the tighter bends.

Send your inquiry to this supplier