Video

1 / 4

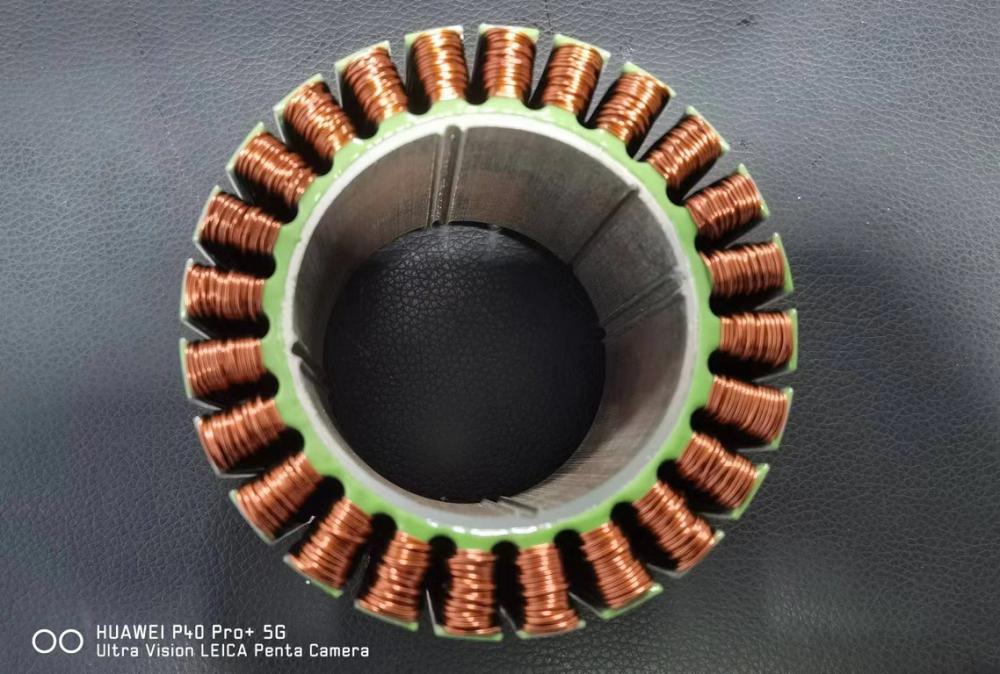

Motor stator powder coating

$90.00

≥100 Piece/Pieces

$88.00

≥500 Piece/Pieces

$86.00

≥1000 Piece/Pieces

$84.00

≥2000 Piece/Pieces

Types:

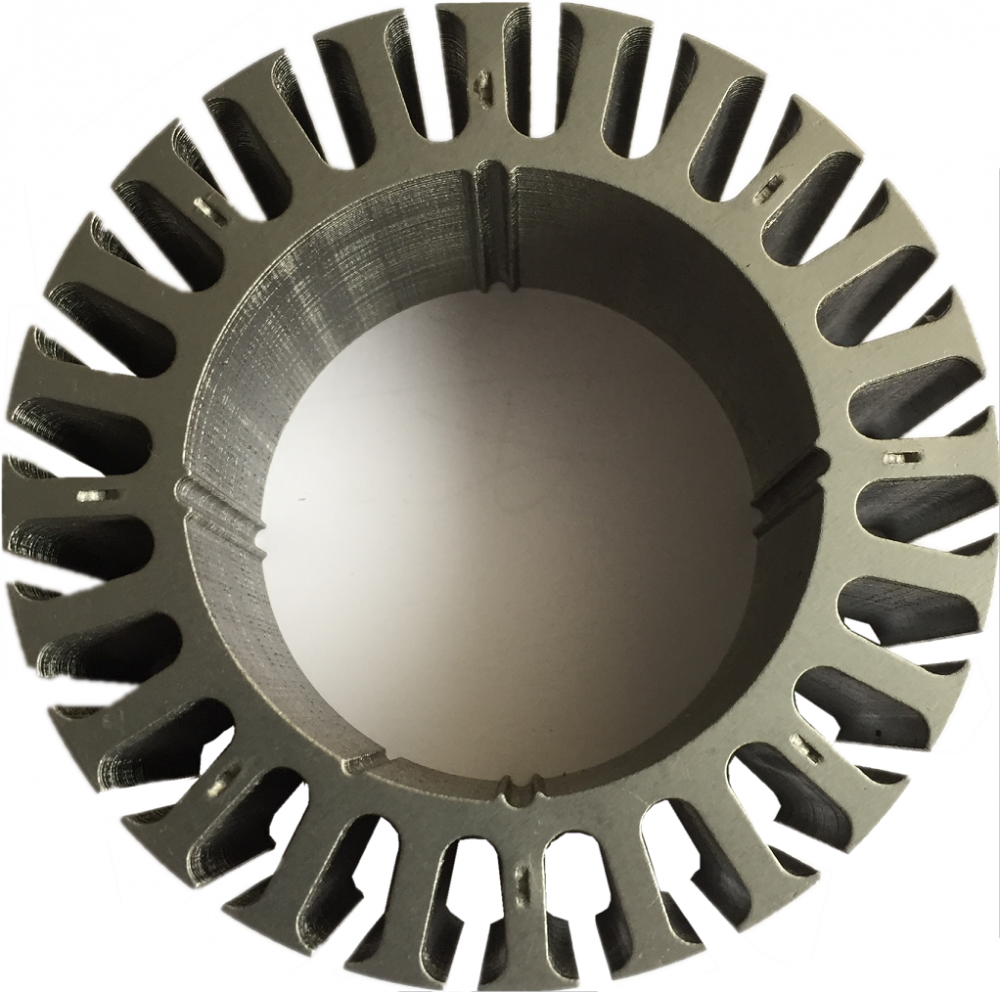

- Laminated Cores

- Rotor

- Stator

Options:

- stator stack

- punching lamination

- stator core

| Model No. : | ATS100 |

|---|---|

| Brand Name : | ATS |

| warranty period : | 3months-1year |

Product description

The performance of an electric motor is closely related to the stator winding. The stator winding is responsible for creating the magnetic field necessary for the motor's operation. The winding design, including the number of turns, wire gauge, and arrangement, determines various motor performance characteristics.

The stator winding affects the motor's efficiency, torque, speed, and power output. The number of turns in the winding determines the strength of the magnetic field generated, which directly affects the motor's torque production. A higher number of turns generally results in higher torque output.

The wire gauge used in the winding affects the motor's resistance and current-carrying capacity. A larger wire gauge can handle higher currents, allowing for increased power output. On the other hand, a smaller wire gauge may result in higher resistance, reducing efficiency and potentially causing overheating.

The arrangement of the stator winding, such as the type of winding (e.g., lap winding, wave winding), also impacts motor performance. Different winding arrangements can affect the motor's speed-torque characteristics, efficiency, and overall performance.

In summary, the design and configuration of the stator winding directly influence the performance of an electric motor, including its torque output, speed, power, and efficiency.

Details pls see below pictures.

| OD | ID | Material | Thickness | Powder coating thickness | Withstand Voltage | Temperature rating | Wire diameter | Application |

| 100mm | 62mm | 50WW400 | 0.5mm | 0.5mm | 800-1400V/AC/0.5mA | B, F, H | 0.65mm | DC Brushless motor |

Video

Send your inquiry to this supplier