Video

1 / 5

Fully automatic hollow concrete block making machine price

Model:

- QT4-15

power:

- 50.88KW

Options:

- Molding Cycle:15S

- Voltage:380/440V

- Weight: 2.5t

- Processing: Brick Molding Machine

| Brand Name : | SIMAMIX |

|---|---|

| Applicable industry : | Machinery Repair Shops,Other |

Zhengzhou, Henan, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

Product description

1: The whole process uses a PLC aptitude control and dialogue system of human-machine interface, easy to analyze the chance

signal, fault diagnosis and parameters setting, ensure the best operation effect of the machine.

2: Interlock between the feeding system and the magazine, the magazine and the door are open/close automatic during feed to ensure

feed quantity, the operation is reliable and suited to long term running.

3: The vertical direction vibration is carried out by hydraulic motor drive vibration unit; the steeples velocity is down by the

electric-hydraulic proportional control technology to ensure the production requirement of difference material.

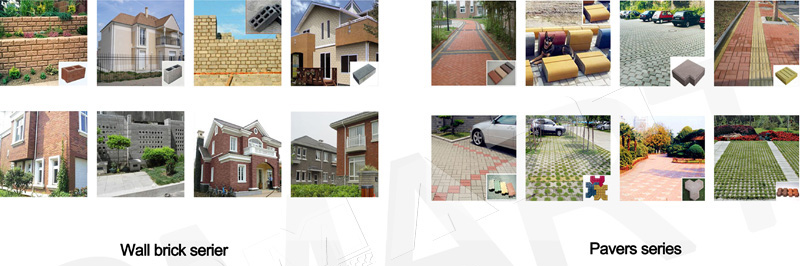

4: Multi use; strong performance; the many kind of products with difference form and size can be made when use the difference mold, such as wall block, honeycomb type block, road block and slope block.

FEATURES

Main Machine

1. This QT12-15 block produce line can use fly ash, slag, gangue, and other kinds of industrial residues then with sand, water, crushed stone, cement all kinds of material to make all kinds of hollow blocks, paver brick, solid bricks just changing the molds. And the percentage of the fly ash can reach 70%.

2. The whole process of this block machine is controlled by PLC and powered by the hydraulic system. Monitoring with the approach switch, machinery, electric, hydraulic and vibrating system work together to make pallets feeding, material feeding, vibrating, the demolding process works automatically. And its characteristic is high efficient, easy-operated and easy-maintained.

Mixing System

The JS series concrete mixer is a double-horizontal-shaft compulsory mixer. This machine has the two advantages of a stand-alone operation and a simple mixing station with the PLD series batching machine. It is a high-efficiency model with a wide range of applications.

Conveyor Belt

The conveyor belt on the brick machine production line can more quickly transport sand, cement and stones to the mixer for mixing, thereby saving labor costs and improving efficiency.

Block Stacker

Automatic Brick Collecting stacker machine System can Collect and stack up produced concrete bricks.meanwhile,it can clean and stack up the pallets. Save 5-6 persons,improve production efficiency.

PLC Control System & Hydraulic System

Control the operation of the brick-making machine: feeding, shaking, pressing, sending, and other operating instructions. Programmable Logic Controller, intelligent control system. There are two modes: automatic mode and manual mode, one-key conversion, the unmanned operation can be realized. Very convenient and easy to operate. The hydraulic station provides power support for the brick machine production line, so that the brick machine can run faster.

Block Mold

The mold of the brick machine is an indispensable part of product production. Used as a model to produce various styles of bricks. The mold uses wire cutting technology to make the mold size more accurate and the cutting surface smoother. Using heat treatment and carburizing technology, the processed mold has higher hardness, more wear resistance, and longer service life.

Our Service

Pre-Sales Service:

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service:

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

Block Application

Customer Visit

Production Process

Video

Zhengzhou, Henan, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier