Video

1 / 4

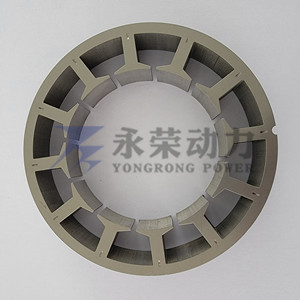

Large Stator Lamination With OD 1120mm Factory

Types:

- Rotor

- Stator

- Explosion-Proof Series

- High Efficiency Series

- Permanent Magnet Series

- Segment Lamination

- High Voltage Series

- Automobile Motor Series

- Custoized Service

| Model No. : | Series Of Y |

|---|---|

| Brand Name : | YONGRONG |

| warranty period : | 3months-1year |

Product description

STATOR INTERLOCKING

Small size but large volume generator and motor lamination is very suitable to be produced in the progressive punching way, which can produce high quantities in a short period of time, even the complete stator & rotor cores. The progressive punching method mainly relies on high-performance and high-speed punches and high-quality molds.

Though dies take a long time to build and cost higher, progressive punching is still the optimal solution for large volume motors. The products produced in this way have a very good consistency.

OPERATION

Cut the silicon steel roll into the required width, and then directly send it to the high-speed press, which can stamp more than one hundred times per minute. Different from other stamping methods, the inside of the tool is complicated, and there are many cutters inside the tool, which respectively complete different steps. There is even a special stacking area inside the tool. The tool can cut out several rivets on each lamination. These rivets are compressed in the stacking area and each lamination is locked to each other.

APPLICATION & COST

The

difference between the rotor speed and the stator magnetic field

rotation speed during the motor operation is the operation of this type

of motor Necessary condition, the speed difference between the two is a

necessary condition for the wire to cut the magnetic line of force to do

work; when the stator is powered off, the electromagnetism of the rotor

part disappears at the same time.

Electrical lamination of mass-produced motors is very suitable to be produced in the progressive punching way, which can produce high quantities of motor laminations or motor cores in a short period of time. Though dies take a long time to build and cost higher, the products produced in this way have a very good consistency.

Henan Yongrong Power Technology Co., Ltd, located in south of Weiwu road, Changge, Henan, China, is a national high-tech enterprise specializing in the R&D and production of stator & rotor lam

Video

Send your inquiry to this supplier